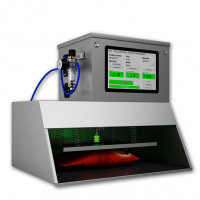

Gas analyser with integrated Leak Detector and Burst Tester combined in in one single instrument

The AtmoCheck® TPC-II DESKTOP sets new standards in quality assurance.

AtmoCheck® TPC-II DESKTOP is a compact analytical instrument specifically designed for the effective random sample inspection of, for example, food packaging.

This adaptable analyser is ideal for quality control in packing areas, and thus improves the economic efficiency of production.

The AtmoCheck® TPC-II DESKTOP is available either as a pure analytical instrument, or optionally an integral leakage test and burst test facility can be incorporated.

The minimal sample gas requirement and the protective atmosphere independent leak test makes the AtmoCheck® TPC-II DESKTOP the perfect quality assurance system that is easy to integrate into production or in the QA laboratory. The automatic test sequence allows you to perform up to 3 tests in one step.

- Automatic analysis of residual oxygen and carbon dioxide content

- Packaging leakage test for leaks < 0.5 μm

- Burst test up to 1,500 mbar

The leak test meets the current standard DIN 55508-1: 02/2018 for leak testing of flexible packaging.

Application Areas

- Analysis of residual oxygen and carbon dioxide content e.g. in MAP packaging

- Leak test of flexible film packaging, vacuum packaging

- Burst testing up to 1,500 mbar

- Suitable for the food and pharmaceutical industry

- Applicable for virtually all types of packaging

AtmoCheck® TPC-II DESKTOP is our top of the range instrument for quality control of for example, food packaging. The analyser can be used for random measurements in both food production areas and in the quality assurance laboratory. Operation via the 10" touch screen display is intuitive, and shows all relevant information on the selected product, measuring progress and limit values.

Analyse the residual oxygen and carbon dioxide concentration of MAP packaging precisely and reliably. Obtain reliable measurement results in the shortest possible time concerning any possible leaks in the packaging with a value < 0.5μm.

Optionally check the burst strength as a final quality test. Detect faulty product packaging via a logical alarm using a "Traffic Light" system. The measurement data memory can be easily integrated into existing network systems. Only if required, the interface can be accessed remotely for easy maintenance. Test the packaging directly in the packaging area, thus shortening downtimes and eliminating complaints and product returns.

Depending on the selected accuracy and detection limit of leakage sizes, all TPC-II analysers are adjusted with calibrated test leaks.

We would be pleased to run a series of tests with you on site.

All Highlights at a glance

- 1 analyser for 3 quality tests

- Highly accurate and rapid O2 and CO2 analysis

- Minimum sample gas requirement

- Precise and fast leak test

- Leakage detection down to <0.5 µm

- Protective atmosphere independent leakage test

- Fully automatic calibration

- Immediate error message in case of over- or underrun the limit values

- Permanent check for clogged filter or suction needle

- Intuitive and simple operation via 10" touch display

- Product menu with fully configurable limit values

- Integrated data logger

- Ethernet connection for integration into networks

- Stainless steel housing

- Test methods according to DIN 55508-1, ASTM F1140, ASTM F2054

Analysis

| Gas type | O2 |

| Measurement procedure | Electrochemical |

| Measuring range | 0-30% / 0-100% |

| Resolution | 0,01% |

| Reproducibility | better 0,2% |

| Service life* | max. 2 Years |

| Gas type | O2 |

| Measurement procedure | Zirconium oxide |

| Measuring range | 0-30% / 0-100% |

| Resolution | 0,01% |

| Reproducibility | better 0,1% |

| Service life* | min. 5 Years |

| Gas type | CO2 |

| Measurement procedure |

NDIR (Infra Red) |

| Measuring range |

0-30% / 0-100% |

| Resolution |

0,01% |

| Reproducibility |

better 0,2% |

| Service life* |

min. 5 Years |

| Other gases on request e.g. ethylene | |

| Sample gas requirement |

ca. 10 ml |

| Measuring speed |

Approx. 10 sec. |

| Calibration |

2 point calibration |

Leak Test

| Measuring principle | Thermal mass flowmeters |

| Measuring range | <0,5-5 µm, 5-150 µm, 50-400 µm |

| Accuracy | +/- 1% |

| Test pressure | 20/30 mbar g |

Burst Tester

| Measuring principle | Overpressure |

| Measuring range | 30-1500 mbar g |

| Accuracy | +/- 1% |

| Resolution | 0,1 mbar g |

General Specifications

| Dimensions | Approx. 370 x 270 x 275 mm |

| Weight | 8 kg |

| Compressed air inlet | 6 mm hose connection (Quick Connector) max. 16 bar g |

| Display | 10“ Touch Display |

| Interfaces | USB, Ethernet |

| Data memory | Unlimited |

| Temperature (gas/environment) | 0-40°C |

| Power supply | 110-240 V. 50-60 Hz |

| Standards/Building Regulations |

- CE conformity |

* Service life of the sensor system depends on ambient conditions and the concentration and degree of contamination of the sample gas.